Setting up a pharmaceutical laboratory in India requires more than just scientific equipment and space. It involves complying with stringent legal, safety, and quality standards laid down by government authorities to ensure public health and safety. This article serves as a complete lab setup guide for pharma companies, startups, and research units looking to establish a compliant and efficient laboratory environment in India.

Whether you are building a new laboratory from scratch or expanding an existing one, it’s essential to understand the key regulatory frameworks, facility design requirements, safety protocols, and documentation needed for a successful and lawful operation.

Why Compliance Matters in Pharmaceutical Lab Setup

Pharmaceutical labs play a crucial role in developing, testing, and validating drugs that eventually reach the public. A minor oversight in infrastructure or compliance can lead to:

- License revocation

- Heavy penalties

- Product recalls

- Risk to human health

To avoid these, your pharmaceutical lab must meet the guidelines defined by the Central Drugs Standard Control Organization (CDSCO), Food and Drug Administration (FDA), Good Laboratory Practices (GLP), and Indian Pharmacopoeia (IP).

Step-by-Step Guide to Setting Up a Laboratory in India

1- Define the Purpose and Scope

Before diving into the technical aspects, determine:

- What kind of tests or research will the lab perform?

- Will it involve microbiological testing, chemical analysis, or formulation development?

- What is the expected sample volume and throughput?

The answers to these will define your equipment needs, space layout, manpower, and documentation requirements.

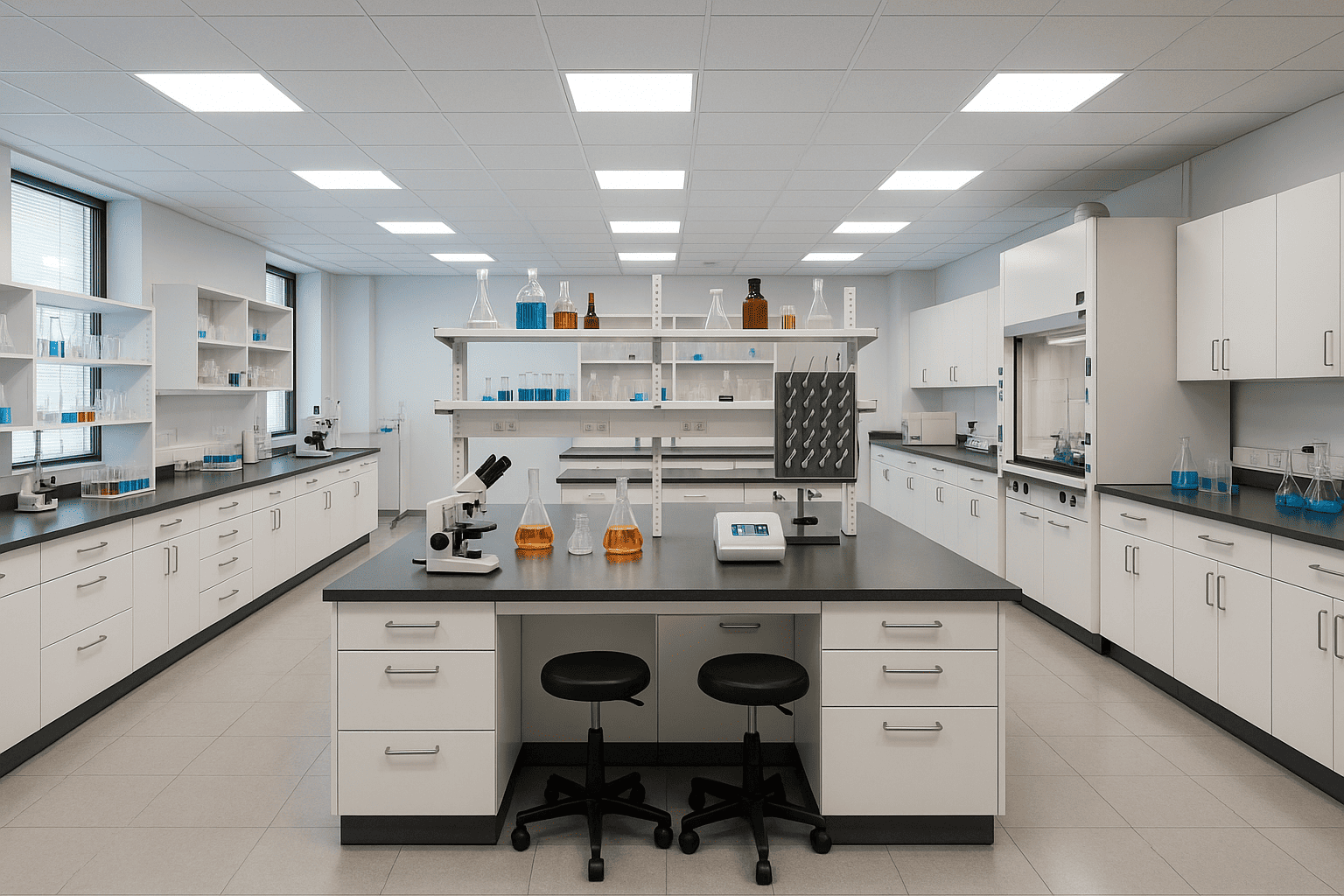

2- Location and Layout Planning

Selecting the right location is vital for regulatory approvals and operational ease. Ensure that the space:

- Is free from industrial pollution

- Has provisions for clean water and waste disposal

- Is away from residential zones (in some states)

The laboratory layout should include:

- Cleanrooms or controlled environments

- Sample reception area

- Analytical and microbiological zones

- Storage for chemicals and samples

- Utilities like HVAC systems, compressed air, and drainage

Reference websites such as chameza.in and labturnkey.in showcase real examples of turnkey lab infrastructure developed with these considerations in mind.

3- Regulatory Registrations and Approvals

Depending on the scale and nature of operations, your pharmaceutical lab will need to register with:

- CDSCO for drug research or clinical trials

- FDA (state-wise) for manufacturing/testing drugs

- BIS for certain equipment certifications

- Local Pollution Control Board for hazardous waste management

Ensure you apply for the necessary licenses and maintain regular compliance audits as per GLP norms.

4- Infrastructure and Equipment Procurement

Once your layout is finalized, begin procurement of:

- Laboratory furniture (anti-vibration tables, chemical-resistant workbenches)

- Biosafety cabinets, fume hoods, and laminar flow systems

- Analytical instruments like HPLC, GC, UV spectrophotometers

- Incubators, ovens, autoclaves, and centrifuges

Always choose equipment compliant with Indian or international quality standards. Companies like labcreator.in offer customized lab furniture and equipment based on your specific research or production needs.

5- Manpower Hiring and Training

A pharma lab must be staffed with qualified personnel:

- Lab Technicians and Analysts with pharma/biotech degrees

- Quality Assurance and Regulatory Officers

- Housekeeping and maintenance staff trained in GMP/GLP

Regular training on safety protocols, sample handling, documentation, and use of Personal Protective Equipment (PPE) is a must.

6- Documentation and SOPs

One of the most overlooked aspects of setting up a laboratory is documentation. You must create:

- Standard Operating Procedures (SOPs) for every task

- Equipment calibration and maintenance logs

- Safety data sheets (SDS) for chemicals

- Staff attendance and training records

- Lab access control and sample tracking records

All documentation should be audit-ready, and updated regularly to comply with regulatory inspections.

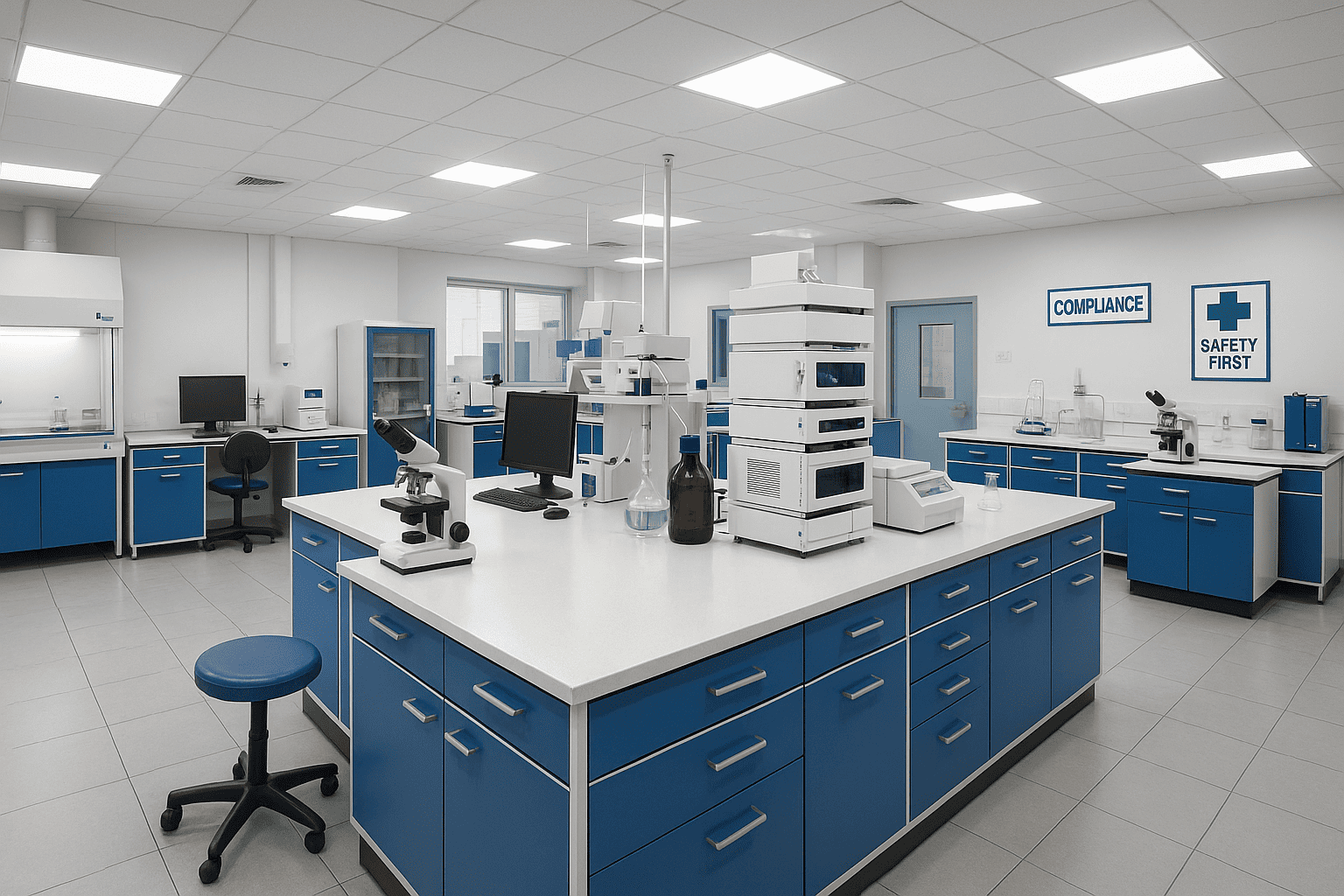

7- Safety and Quality Compliance

Pharmaceutical labs deal with volatile chemicals, biological agents, and sensitive drugs. Ensure compliance with:

- Fire safety norms (ABC extinguishers, fire alarms, exits)

- Waste management protocols for biohazards and solvents

- Water and air filtration systems (HEPA filters, RO units)

- Pest control and cleanliness as per GMP

Your laboratory setup must include clear signage, emergency eye wash stations, first aid kits, and 24×7 monitoring via CCTV.

Estimated Lab Setup Cost in India

The lab setup cost depends on multiple factors:

| Parameter | Approximate Cost (INR) |

| Basic infrastructure (civil, electrical, HVAC) | ₹10 – ₹30 Lakhs |

| Furniture & Fixtures | ₹5 – ₹15 Lakhs |

| Lab Equipment & Instruments | ₹20 – ₹100 Lakhs |

| Licenses & Compliance | ₹1 – ₹5 Lakhs |

| Staff Hiring & Training | ₹5 – ₹10 Lakhs annually |

Thus, a mid-size pharmaceutical lab can cost anywhere between ₹40 lakhs to ₹1.5 crores depending on the specialization and quality standards.

Disclaimer:

The estimated lab setup cost in India provided above is indicative only and may vary significantly based on multiple factors. These prices are not fixed and should be considered a general reference to assist in preliminary budgeting.

Factors that can influence lab setup cost include:

- Size and scope of the laboratory

- Type of pharmaceutical work (R&D, QC, formulation, testing, etc.)

- Location of the facility (urban, semi-urban, industrial zone)

- Choice of materials, brands, and specifications for lab furniture and equipment

- Type of HVAC, air filtration, and cleanroom standards required

- Regulatory compliance level (GLP, GMP, FDA, NABL, etc.)

- Availability and cost of skilled manpower

- Logistics, shipping, and import duties on certain equipment

- Customizations or future-proofing in design and utilities

We recommend consulting professional turnkey lab setup consultants (e.g., chameza.in, labturnkey.in, labcreator.in) for a site-specific and accurate cost estimation before making any investment decisions.

Common Pitfalls to Avoid

While following a lab setup guide, make sure to avoid the following:

- Not planning for future expansion or equipment upgrades

- Ignoring air quality and humidity controls

- Using domestic-grade furniture or storage in pharma zones

- Missing out on GLP documentation from day one

- Skipping safety audits or mock fire drills

Being proactive in compliance can save you years of rework and legal complications.

Conclusion

Setting up a pharmaceutical lab in India is a multi-step process involving regulatory clearances, infrastructure planning, equipment sourcing, safety systems, and qualified staff. With the right laboratory setup approach, your lab can become a benchmark of quality, innovation, and safety.

If you are planning to enter this sector, make sure you consult reliable turnkey solution providers like chameza.in, labturnkey.in, or labcreator.in who bring years of experience in compliant laboratory setups.

This lab setup guide is designed to simplify your journey into pharmaceutical research and development while ensuring you meet every legal and operational requirement.