Industrial infrastructure is going through a major shift. The pace of modernization, automation, and sustainability demands has never been higher. Companies no longer want just a supplier or contractor — they need a single, accountable partner who can deliver an entire facility ready for operation. That’s where Turnkey Project Management comes in.

What’s Changing in 2025

Let’s start with the big picture. In 2025, industries are under pressure to build faster, smarter, and cleaner. Manufacturing plants, laboratories, and logistics hubs are being designed with sustainability and digital efficiency at their core.

Traditional project delivery — where design, procurement, and construction are handled by different vendors — often leads to delays, budget overruns, and communication gaps. In contrast, a Turnkey Project model consolidates everything under one roof: design, engineering, procurement, construction, and even commissioning.

This “single-window” approach means businesses can focus on their core operations while a professional team takes care of the entire setup. It’s not just convenient — it’s strategic.

The Core Idea Behind Turnkey Project Management

Here’s the thing: Turnkey Project Management isn’t just about completing a job — it’s about delivering a fully functional asset that’s ready to run from day one. The client doesn’t have to coordinate between multiple agencies. Instead, they sign one contract and deal with one point of contact who takes responsibility for time, cost, and quality.

This model works especially well for industrial sectors like pharmaceuticals, chemicals, food processing, research laboratories, and heavy manufacturing — where precision, compliance, and speed matter equally.

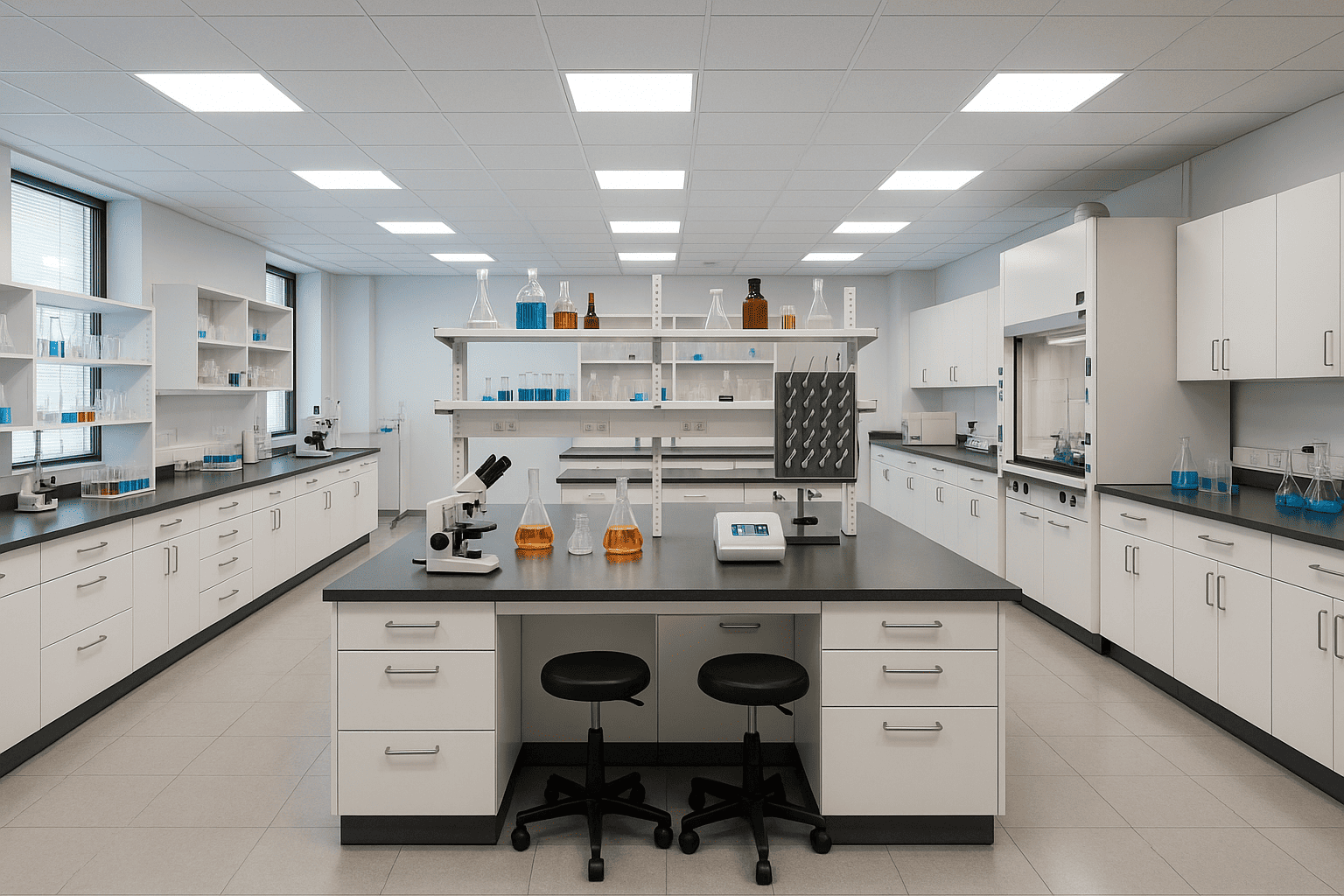

For example, if a lab equipment manufacturer wants to set up a new production facility, the turnkey partner handles everything — from site analysis, architectural design, and regulatory approvals to final machine installation and testing. The result? The client walks into a ready-to-operate facility without the typical chaos of managing multiple vendors.

Why It Matters for Industrial Infrastructure

Industrial infrastructure today is more complex than ever. It involves integrating energy-efficient systems, automation, smart monitoring, and environmental standards — all while staying within budget.

Turnkey Project Management simplifies this complexity by aligning every phase under a single strategic framework. The project manager ensures all technical teams, architects, engineers, and suppliers are working toward the same goal — efficient completion with zero compromise on quality.

This unified command structure reduces rework, improves coordination, and ensures that every decision — from selecting materials to choosing automation systems — contributes to long-term operational efficiency.

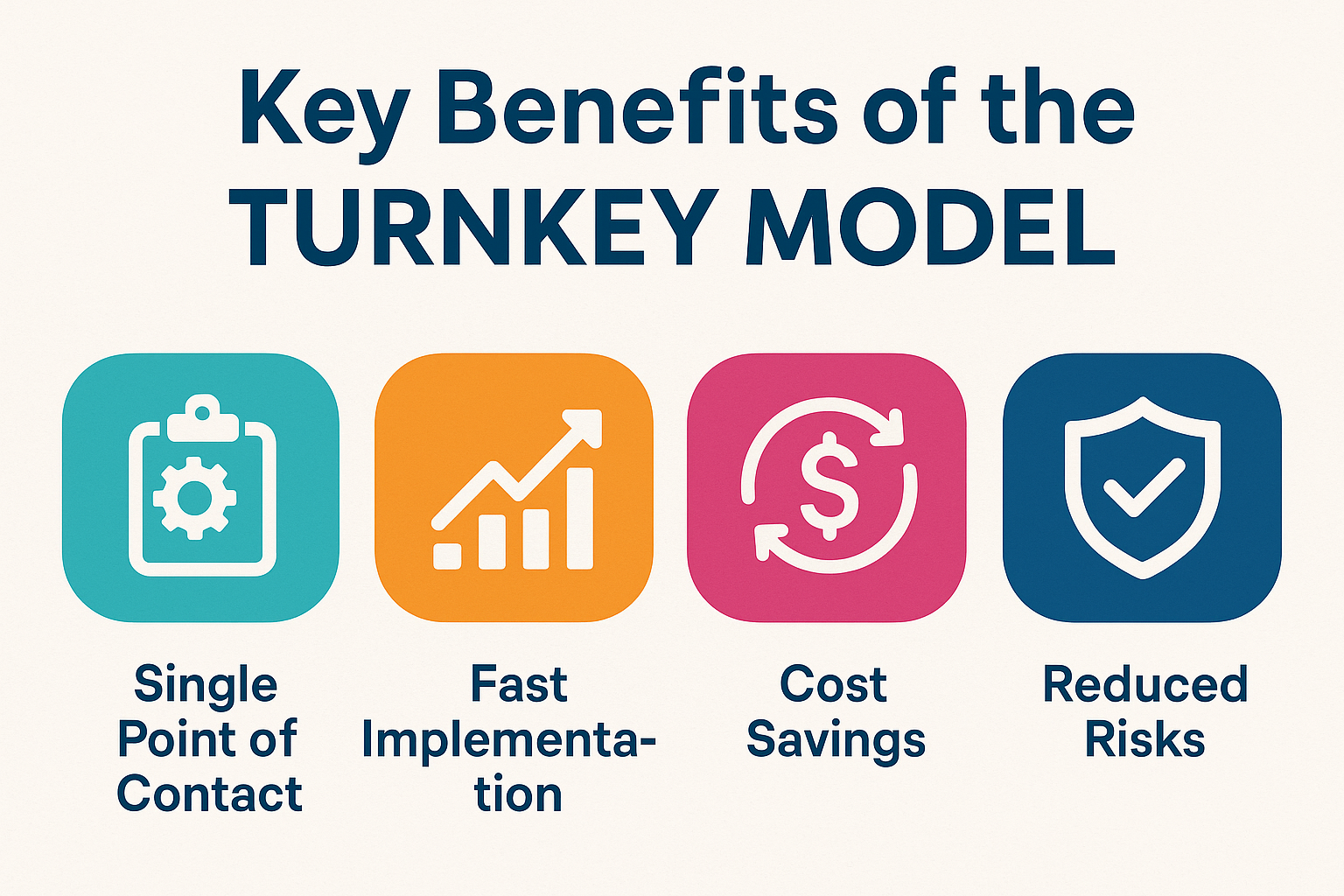

Key Benefits of the Turnkey Model

Let’s break down the main advantages:

1- Speed and Efficiency

With a Turnkey Project, timelines are predictable because design, procurement, and construction are handled simultaneously. There’s no waiting for approvals between disconnected teams — everything moves in sync.

2- Single Accountability

You deal with one partner who takes responsibility for design errors, construction quality, and delivery time. That means fewer disputes and faster decision-making.

3- Cost Control

Because the pricing and deliverables are agreed upon upfront, cost overruns are rare. The turnkey partner bears the risk of managing materials, labor, and logistics within the defined budget.

4- Quality Assurance

Every element — from structural design to electrical installation — is done according to pre-approved standards. Quality checks are built into each phase of the process.

5- Technology Integration

In 2025, digital tools are central to infrastructure planning. Turnkey providers are increasingly using Building Information Modeling (BIM), drones, and IoT systems to track progress, reduce waste, and monitor performance in real time.

Sustainability as a Core Value

Sustainability isn’t a buzzword anymore — it’s a business necessity. Industries are expected to build energy-efficient, environmentally compliant facilities.

A Turnkey Project approach allows sustainability to be built into the design itself, not added as an afterthought. The project team can optimize building orientation, ventilation, waste management, and energy systems right from the start. This results in lower operating costs and long-term environmental benefits.

The Role of Digitalization

Another big reason for the rise of Turnkey Project Management is digital transformation. Every phase — from planning to handover — is now data-driven.

Cloud-based project dashboards provide real-time visibility into progress, budgets, and resource allocation. Digital twins — virtual models of real assets — allow engineers to predict issues before they happen. Even maintenance schedules are planned before the facility goes live.

This combination of physical construction and digital insight is redefining how industrial infrastructure is built and managed.

Real-World Example

Imagine a pharmaceutical company expanding its production capacity. It doesn’t have the internal resources to manage a large construction project. Instead, it hires a turnkey contractor.

The contractor designs the plant layout, gets necessary approvals, sources specialized equipment, constructs the facility, installs cleanroom systems, and sets up utility lines. Within months, the plant is fully operational — with production ready to start immediately.

That’s the power of an integrated Turnkey Project approach: faster delivery, fewer headaches, and guaranteed quality.

Challenges to Consider

Of course, it’s not all smooth sailing. Like any system, turnkey delivery has its challenges. The client must choose a reliable partner with proven technical expertise and transparent processes.

Since one company handles everything, a weak contractor can cause major setbacks. That’s why clear contracts, milestone-based payments, and regular project reviews are essential.

Communication also plays a key role. The client should stay informed about progress, quality checks, and any scope changes — even if they’re not managing day-to-day operations.

What’s Next for Turnkey Projects in 2025 and Beyond

The future of Turnkey Project Management looks strong. Industrial investors are increasingly valuing speed, integration, and predictability — all of which this model delivers.

With the rise of smart factories and digital infrastructure, turnkey partners are evolving too. They’re no longer just builders; they’re technology enablers, integrating automation, AI-driven maintenance, and sustainability into every phase.

Governments are also pushing for faster industrial development, especially in sectors like renewable energy, pharmaceuticals, and defense. That means more opportunities for companies offering full-scope Turnkey Project solutions.

Final Thoughts

In 2025, the industrial world is no longer asking, “Who can build this?” but “Who can deliver this — ready to run?” That’s the essence of Turnkey Project Management.

It’s about trust, accountability, and precision — not just construction. When done right, it transforms how industries grow, operate, and compete. Whether it’s a high-tech manufacturing plant, a research lab, or a large-scale logistics center, the turnkey approach ensures the final result is exactly what the business envisioned — efficient, future-ready, and built for success.