The laboratory design landscape is evolving faster than ever. With research methods changing, new technologies emerging, and industries demanding more adaptable facilities, the debate between Modular Lab Design and Custom Lab Design has become increasingly relevant. As we move toward 2026 and beyond, organizations are asking: which approach will future-proof their laboratory?

Below is an in-depth look at the latest trends, strengths, and long-term potential of both options and how to decide which fits your vision.

Understanding the Two Approaches

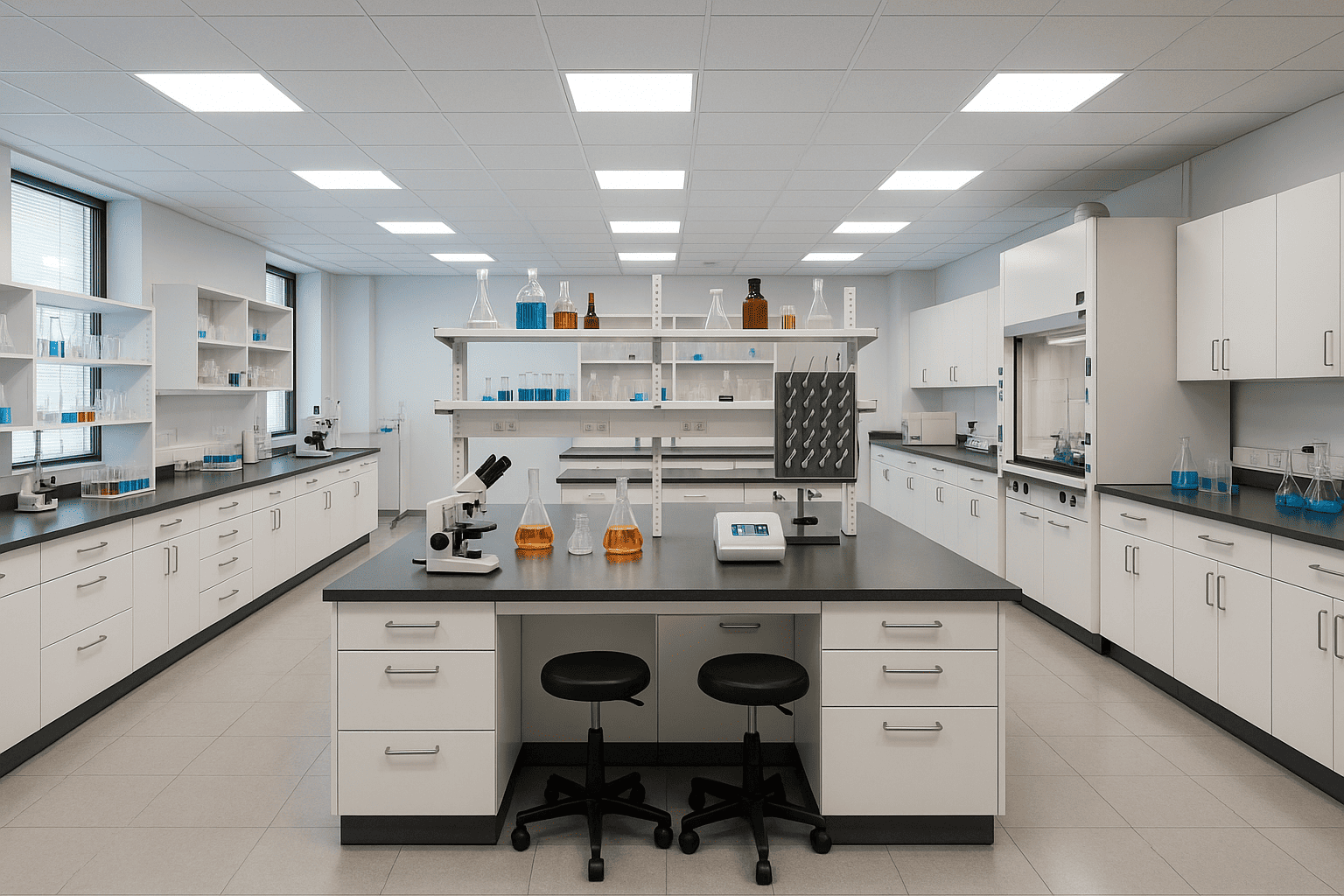

Modular Lab Design

Modular Lab Design uses pre-engineered, standardized components such as benches, storage units, service panels, and wall systems. These modules can be rearranged, expanded, or replaced without major demolition or reconstruction. It’s the laboratory equivalent of building with flexible, interchangeable blocks.

Custom Lab Design

Custom Lab Design is built from the ground up according to exact functional requirements. Everything layout, materials, utilities, furniture dimensions, ventilation systems is tailored to perfectly match the lab’s activities, equipment, and workflows.

Both approaches have their place, but their relevance is shifting as technology, budgets, and industry demands evolve.

Why Modular Lab Design Is Becoming a Power Trend for 2026

1- Speed and Ease of Deployment

One of the strongest trends going into 2026 is the increasing need for rapid lab setup. Industries like biotechnology, diagnostics, and pharma are scaling faster than traditional construction timelines allow.

Modular Lab Design enables:

- Shorter build times

- Quick installation

- Minimal disruption to existing operations

- Faster certification and commissioning

This speed advantage is becoming a critical factor for organizations trying to stay competitive.

2- Flexible, Future-Ready Spaces

Research priorities can shift unexpectedly, and modern labs must be prepared for such change. Modular systems provide:

- Reconfigurable workstations

- Mobile benches and storage

- Upgradable service panels

- Easy expansion when teams grow

This adaptability makes Modular Lab Design ideal for labs dealing with diverse or fast-evolving workflows.

3- Cost Efficiency Over Time

While modular solutions may have similar upfront costs to traditional designs, they typically win in the long run because:

- Reconfiguration costs are significantly lower

- There’s less construction waste

- Components can be reused or replaced individually

- Downtime is minimized

With budgets tightening in many industries, long-term cost efficiency is a major benefit.

4- Sustainability and Green Lab Goals

As global sustainability goals become stricter, Modular Lab Design offers advantages such as:

- Reduced on-site waste

- Use of recyclable materials

- Lower energy consumption through optimized systems

- Ability to upgrade equipment without rebuilding entire sections

This makes modular solutions attractive for institutions pursuing green certifications.

Why Custom Lab Design Still Matters in 2026

While modular solutions are gaining momentum, Custom Lab Design isn’t fading. In fact, it remains essential for several specialized sectors.

1- Precision Tailoring for Specialized Research

Certain labs especially in pharmaceuticals, chemical analysis, heavy equipment testing, and regulated environments have highly specific requirements. Custom design ensures:

- Exact workflow optimization

- Specialized storage solutions

- Equipment-specific bench height and load capacity

- Purpose-built ventilation and exhaust

When precision is non-negotiable, Custom Lab Design excels.

2- Better Compliance for Strict Regulatory Standards

Industries like pharma, food testing, and cleanrooms require tightly controlled spaces. Custom Lab Design makes it easier to integrate:

- Class-specific cleanroom systems

- Customized containment areas

- Special waste management systems

- Highly specialized HVAC integration

Modular components often cannot meet these ultra-specific requirements without modification.

3- Maximum Space Optimization

For labs with unusual building shapes or tight spaces, custom layouts ensure:

- No wasted corners

- Efficient workflow routes

- Perfectly fitted furniture

- Purpose-designed utility access

A custom plan can deeply optimize space something modular options might not achieve as precisely.

Emerging Trends Influencing Both Lab Types in 2026

Regardless of whether you choose modular or custom, upcoming design trends are shaping how labs will look and function.

1- Smart Lab Integration

Labs of 2026 and beyond will incorporate:

- IoT devices

- Automated sample processing

- Digital monitoring

- Energy-efficient smart lighting

- Sensor-driven environmental controls

Modular labs integrate these upgrades easily, while custom labs must plan ahead to avoid costly future redesigns.

2- Multi-Functional Hybrid Spaces

Research teams now work across wet labs, dry labs, computational zones, and collaborative areas. Laboratories increasingly need:

- Shared workspaces

- Convertible research bays

- Movable storage and equipment

- Soundproof digital analysis rooms

Modular systems naturally support this hybrid trend, though custom layouts can achieve it with thoughtful planning.

3- Sustainability Standards and Energy Efficiency

Environmental responsibility is now a key design factor. Both modular and custom labs are incorporating:

- Low-VOC materials

- Optimized ventilation

- Solar or alternative power infrastructure

- Water-efficient utilities

- Energy-saving lighting and climate systems

Sustainability is no longer optional it’s becoming a design requirement.

Modular vs. Custom Lab Design: Which Will Dominate 2026

The answer isn’t one-size-fits-all.

Choose Modular Lab Design if you need:

- Flexibility and frequent reconfiguration

- Rapid setup and lower operational downtime

- Incremental expansion

- Affordability through reduced rework

- Easy integration of future technologies

Modular labs are ideal for start-ups, academic institutions, diagnostics, R&D units, and fast-growing companies.

Choose Custom Lab Design if you need:

- Highly specialized workflows

- Heavy or unique equipment integration

- Strict compliance and containment

- Long-term fixed operations

- Tailor-made space efficiency

Custom labs are best for pharma manufacturing, QC labs, chemical labs, cleanrooms, and high-precision research environments.

The Hybrid Model: The Best of Both Worlds

A growing trend for 2026 is hybrid lab design, which uses modular components for general zones and custom elements for specialized areas. This approach delivers:

- Flexibility

- Lower costs

- Optimal workflow control

- Future-ready adaptability

It is increasingly becoming the preferred choice for organizations that want both stability and agility.

Conclusion

As research environments evolve, so does the debate around Modular vs. Custom Lab Design. Modular solutions are on the rise thanks to flexibility, cost efficiency, and rapid deployment, while custom designs continue to shine in specialized, regulated, or precision-driven environments.

Looking toward 2026 and beyond, the most successful labs will be those that remain adaptable, sustainable, and digitally integrated whether through modular, custom, or hybrid design strategies.