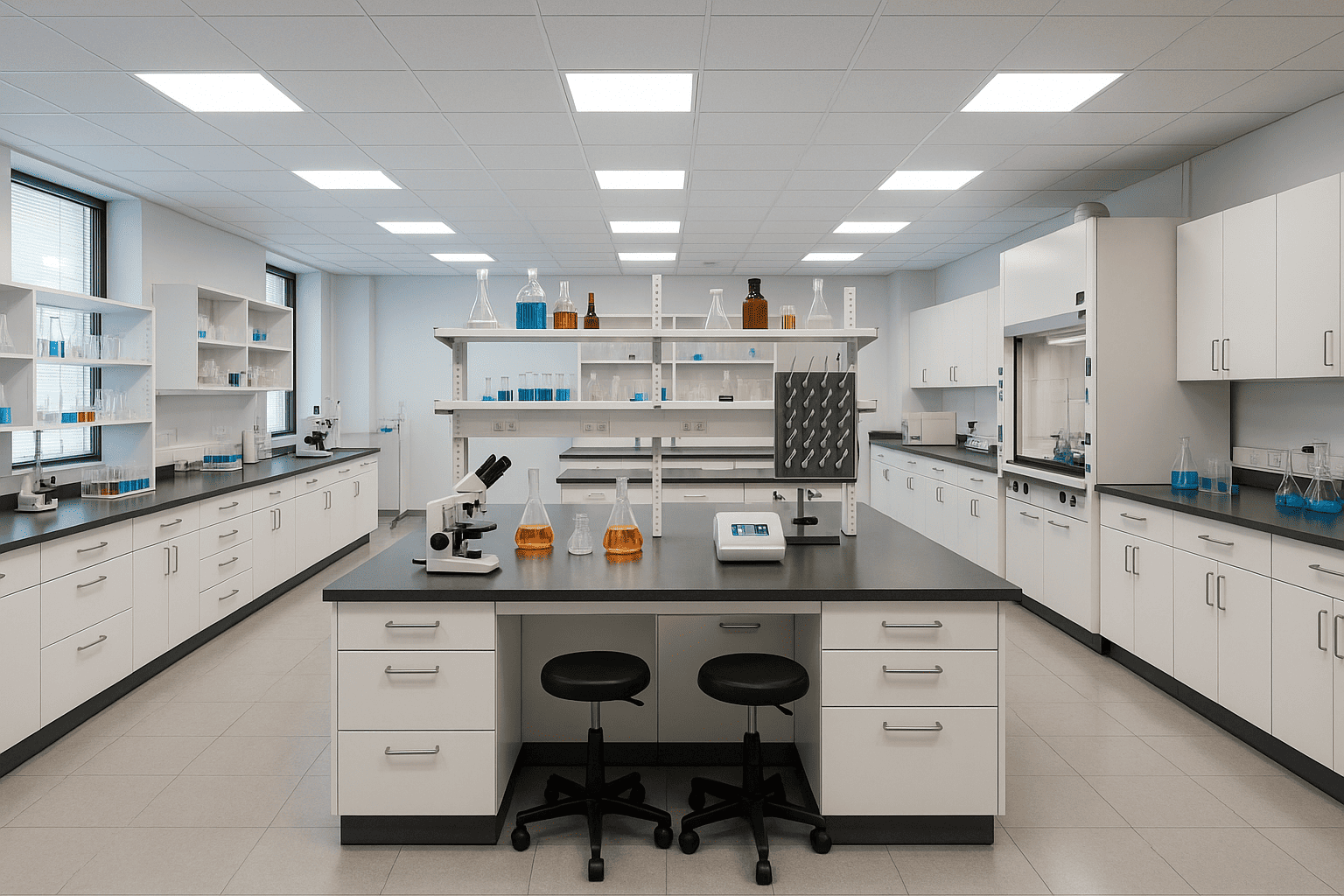

Laboratories are controlled technical environments where accuracy, safety, and compliance are critical. Whether it’s a pharmaceutical lab, chemical research facility, microbiology lab, or educational institution, the performance of the Heating, Ventilation and Air Conditioning (HVAC) system plays a direct role in maintaining environmental quality. Designing HVAC for laboratories requires much more than temperature control—it demands precise management of air quality, pressure, humidity, and contamination risks. A well-designed lab ventilation system not only improves safety but also boosts operational efficiency and regulatory compliance.

In this article, we explore the essential key design parameters of laboratory HVAC design, helping engineers, facility managers, and industry professionals understand what it takes to create a safe and efficient laboratory environment.

1- Importance of HVAC in Laboratory Environments

Laboratories deal with sensitive experiments, volatile chemicals, biological agents, and specialized instruments. Any deviation in environmental conditions can impact experiment accuracy, compromise safety, or violate industry standards. Therefore, HVAC for laboratories ensures:

- Contaminant control

- Stable temperature and humidity

- Proper dilution and exhaust of harmful gases

- Safe working conditions for researchers

- Energy-efficient operation

Regulatory bodies like ASHRAE, OSHA, and ISO consider HVAC design a core part of laboratory safety certifications.

2- Airflow Patterns and Ventilation Rates

One of the primary design considerations is how air moves through the space. A laboratory must always maintain a directional airflow from clean to contaminated areas. This ensures that fumes, aerosols, and particles do not migrate into office spaces or corridors.

Key Considerations:

- Air Changes Per Hour (ACH):

Laboratories typically require 6–12 ACH, depending on the hazard level. - Fume Hoods and Exhaust Integration:

Every fume hood adds additional ventilation demand, making the lab ventilation system more complex. - Unidirectional Flow:

Helps minimize turbulence and reduce cross-contamination between work zones.

Proper airflow design ensures that hazardous substances are continuously removed from the workspace.

3- Pressure Control and Room Pressurization

Maintaining the right pressure differentials is essential for contamination control. Based on the lab’s purpose, the room may need to be either negatively or positively pressurized.

Negative Pressure Labs

Used in chemical, microbiology, and biosafety labs where hazardous materials are present.

- Air flows into the lab but cannot escape to adjacent spaces.

- Protects the external environment from exposure.

Positive Pressure Labs

Used in clean laboratories such as pharmaceutical QC labs or electronics testing areas.

- Air flows outward to prevent contamination from entering.

A robust laboratory HVAC design calculates appropriate pressure setpoints, ensures continuous stability, and incorporates alarms for pressure loss or equipment failure.

4- Temperature and Humidity Control

Precise thermal control is essential—not only for comfort, but also for equipment stability and chemical behavior. Many experiments require consistent conditions to produce reliable results.

Typical Setpoints

- Temperature: 20–24°C (varies by application)

- Humidity: 30–60% RH

- Microbiology labs often require lower humidity to limit microbial growth

- Chemical labs need stable RH to prevent reactions or corrosion

Advanced HVAC systems include sensors, VAV (Variable Air Volume) controls, reheat coils, and humidifiers/dehumidifiers to maintain narrow environmental tolerances.

5- Filtration and Air Quality Management

Air filtration is vital for both safety and compliance. Laboratories require multiple levels of filtration to remove particulates, bacteria, viruses, and chemical contaminants.

Filtration Components

- Pre-filters: Capture large particles

- Fine filters (F7–F9): Remove finer dust and aerosols

- HEPA filters: Used in biosafety labs for pathogen containment (99.97% efficiency at 0.3 microns)

- Activated carbon filters: Remove chemical vapors and odor-causing compounds

A good lab ventilation system incorporates filtration options based on the lab’s risk level and the types of experiments performed.

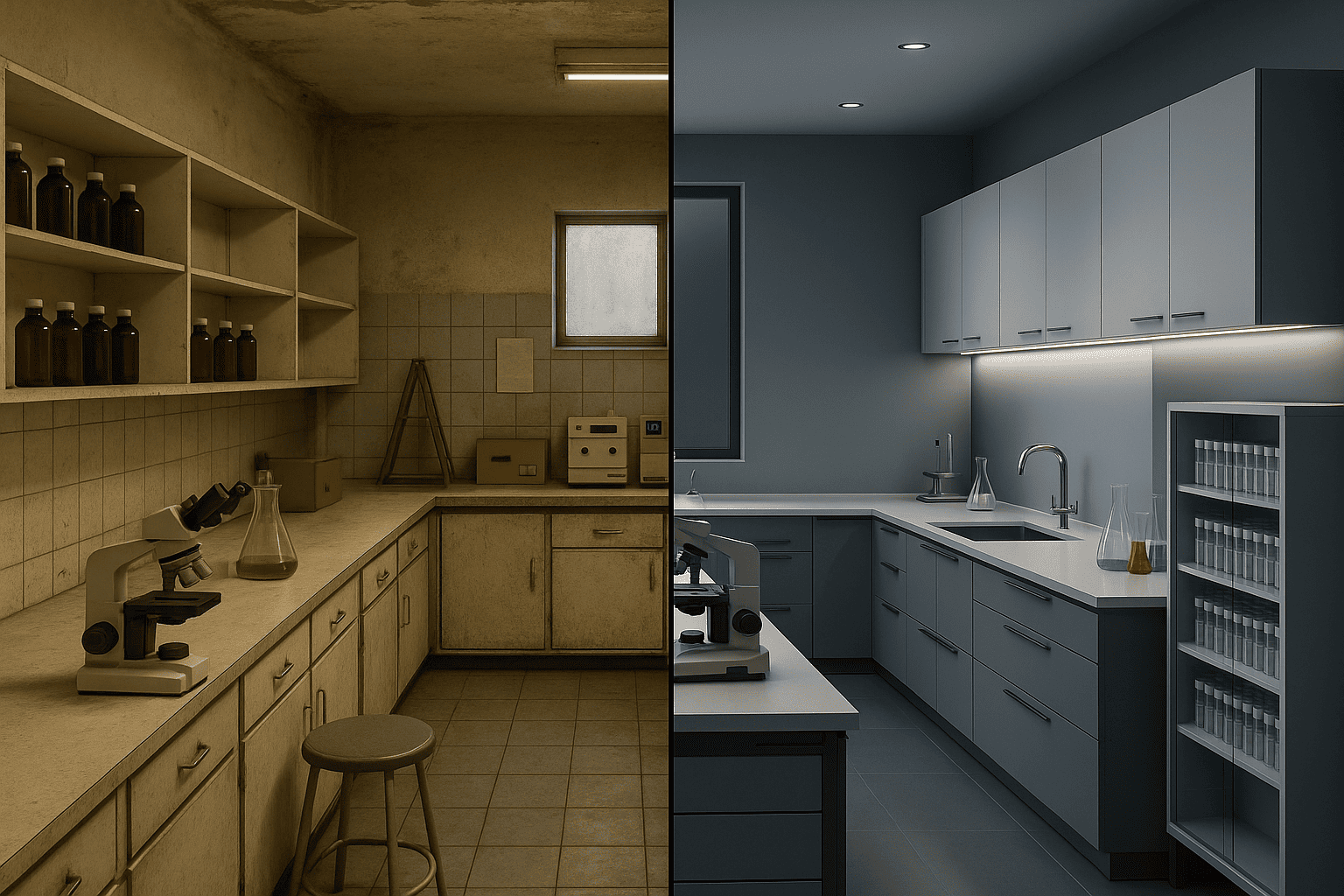

6- Energy Efficiency and Sustainability

Laboratories consume up to 5–10 times more energy than office buildings due to high ventilation requirements. Designing an efficient system reduces operational expenses and environmental impact.

Energy-Saving Strategies

- Demand-controlled ventilation (DCV) to adjust fresh air based on occupancy

- Variable air volume (VAV) systems instead of constant volume

- Heat recovery units to reuse exhaust air energy

- Smart building automation systems (BAS) for real-time optimization

Green lab initiatives and sustainable design can result in high efficiency without compromising safety.

7- Integration of Safety Equipment

An efficient laboratory HVAC design must integrate the following systems seamlessly:

- Fume hoods

- Biological safety cabinets

- Chemical storage exhausts

- Cleanroom airlocks

- Emergency purge systems

Improper integration can lead to airflow imbalance, pressure fluctuations, and safety hazards.

8- Compliance and Standards

HVAC designs for labs must follow strict guidelines set by:

- ASHRAE 62.1 and 110

- OSHA laboratory standards

- ISO cleanroom classifications

- Biosafety Level (BSL) guidelines

Compliance ensures laboratories are safe, audit-ready, and legally protected.

9- Commissioning and Performance Testing

Even the best designs require thorough testing before a lab becomes operational. Commissioning teams evaluate:

- Airflow patterns

- Pressurization stability

- HEPA filter integrity

- Temperature and humidity uniformity

- Ventilation system responsiveness

Regular maintenance and recalibration ensure long-term system reliability.

Conclusion

Designing HVAC for laboratories is a multidisciplinary process that focuses on safety, precision, and operational efficiency. From airflow and pressurization to humidity control and filtration, every element plays a vital role in protecting researchers, experiments, and the surrounding environment. A well-engineered laboratory HVAC design ensures that scientific work continues smoothly while meeting the highest performance and compliance standards.

As laboratories evolve with modern technologies and sustainability goals, HVAC systems must keep up with advanced controls, energy-efficient features, and robust safety mechanisms. Ultimately, a carefully designed lab ventilation system is the backbone of a safe, compliant, and productive laboratory environment.