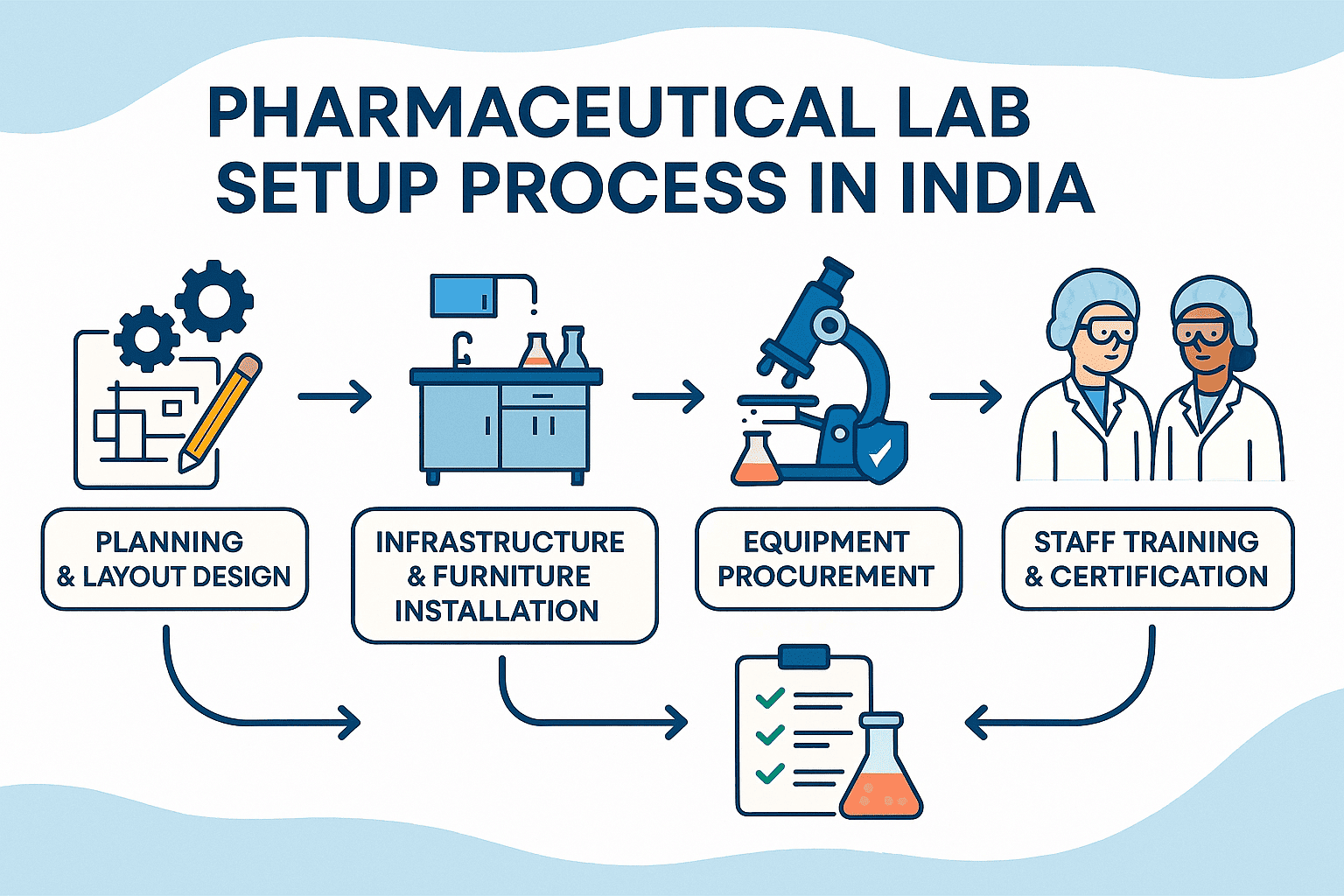

Setting up a pharmaceutical laboratory in India requires a well-structured plan that meets both scientific needs and regulatory compliance. The pharmaceutical industry operates under strict quality and safety standards, making a laboratory the heart of any successful operation. Whether the lab is for drug research, testing, or quality control, understanding the Lab Setup Requirements is crucial for efficiency, reliability, and certification.

1- Understanding the Purpose of a Pharmaceutical Laboratory

Before starting any lab project, it’s important to define its purpose clearly. Pharmaceutical companies generally build laboratories for specific functions such as:

- Research and Development (R&D): For developing new drug formulations and conducting stability studies.

- Quality Control (QC): For testing raw materials, intermediates, and final products to meet pharmacopeia standards.

- Microbiology Laboratories: For microbial limit testing, sterility testing, and environmental monitoring.

- Analytical Laboratories: For chemical analysis using instruments like HPLC, GC, UV-Vis spectrophotometers, and more.

Defining the objective helps in selecting the right layout, instruments, and team for smooth operation and compliance.

2- Essential Infrastructure and Layout Planning

The physical layout of a pharmaceutical lab must ensure safety, efficiency, and hygiene. When planning Lab Setup Requirements in India, consider the following aspects:

- Space Planning: Sufficient space for instruments, testing areas, and movement. Avoid congestion to minimize contamination risks.

- Zoning: Separate areas for different activities—sample receipt, analysis, documentation, and waste disposal.

- Material Flow: Design should allow smooth movement of personnel and materials without cross-contamination.

- Ventilation and Air Handling: Install advanced HVAC systems with HEPA filters to maintain air quality.

- Lighting and Flooring: Use bright, shadow-free lighting and anti-static, chemical-resistant flooring to ensure safety.

An efficient layout not only boosts productivity but also ensures compliance with Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP) standards.

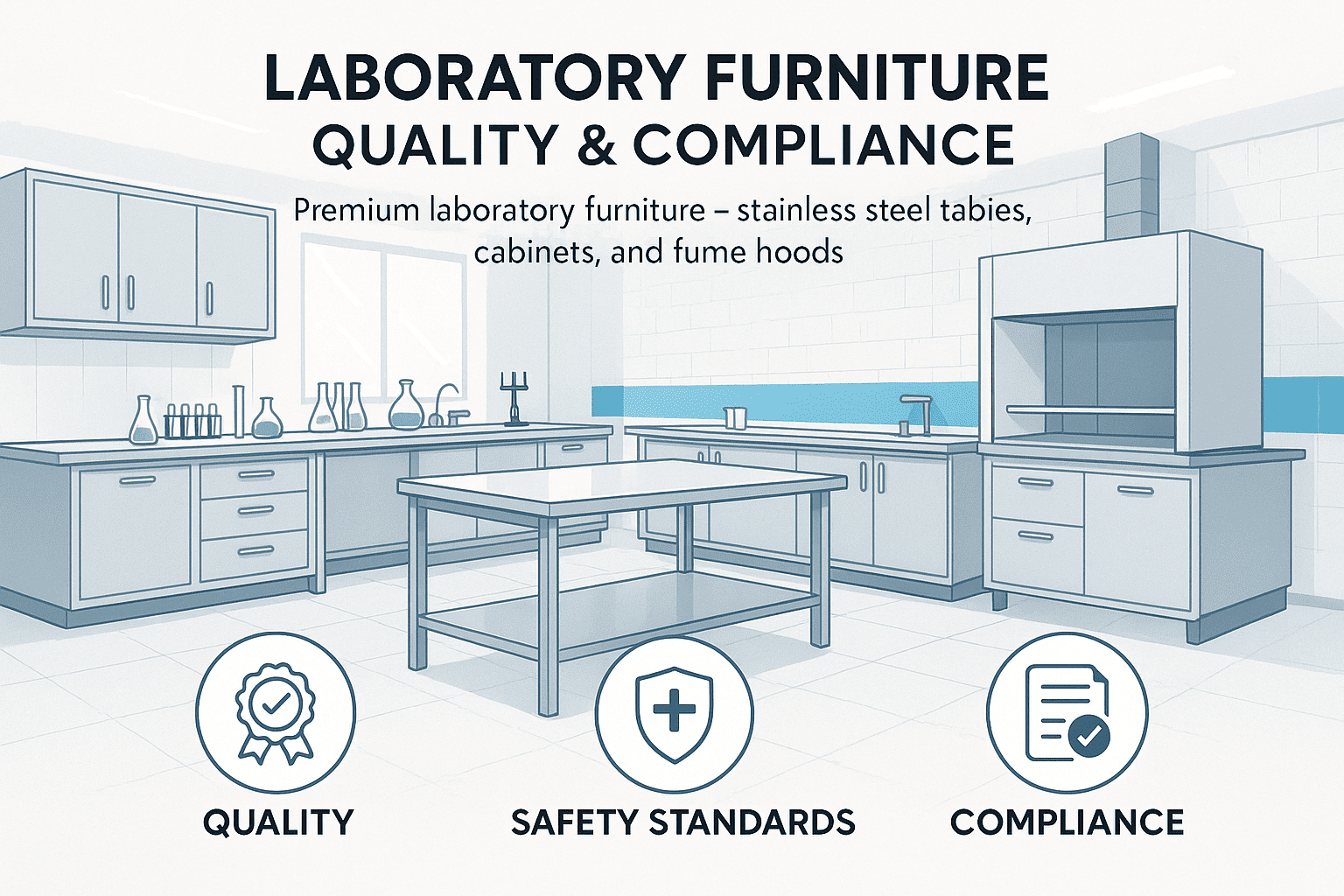

3- Furniture and Equipment Selection

Laboratory furniture and equipment form the backbone of any pharmaceutical setup. Durable, ergonomic, and modular designs are preferred for long-term performance. Here’s what to include:

- Workbenches: Chemical-resistant tops with built-in sinks and reagent racks.

- Storage Cabinets: For acids, flammables, and solvents.

- Fume Hoods and Biosafety Cabinets: For handling hazardous materials safely.

- Analytical Instruments: HPLC, GC, FTIR, UV-Vis spectrophotometer, and pH meters.

- Refrigeration Units: For storing samples and reagents at specific temperatures.

- Autoclaves and Incubators: Essential for sterilization and microbial growth testing.

The selection must align with the lab’s function, budget, and maintenance capabilities. Always choose vendors that comply with Indian and international standards.

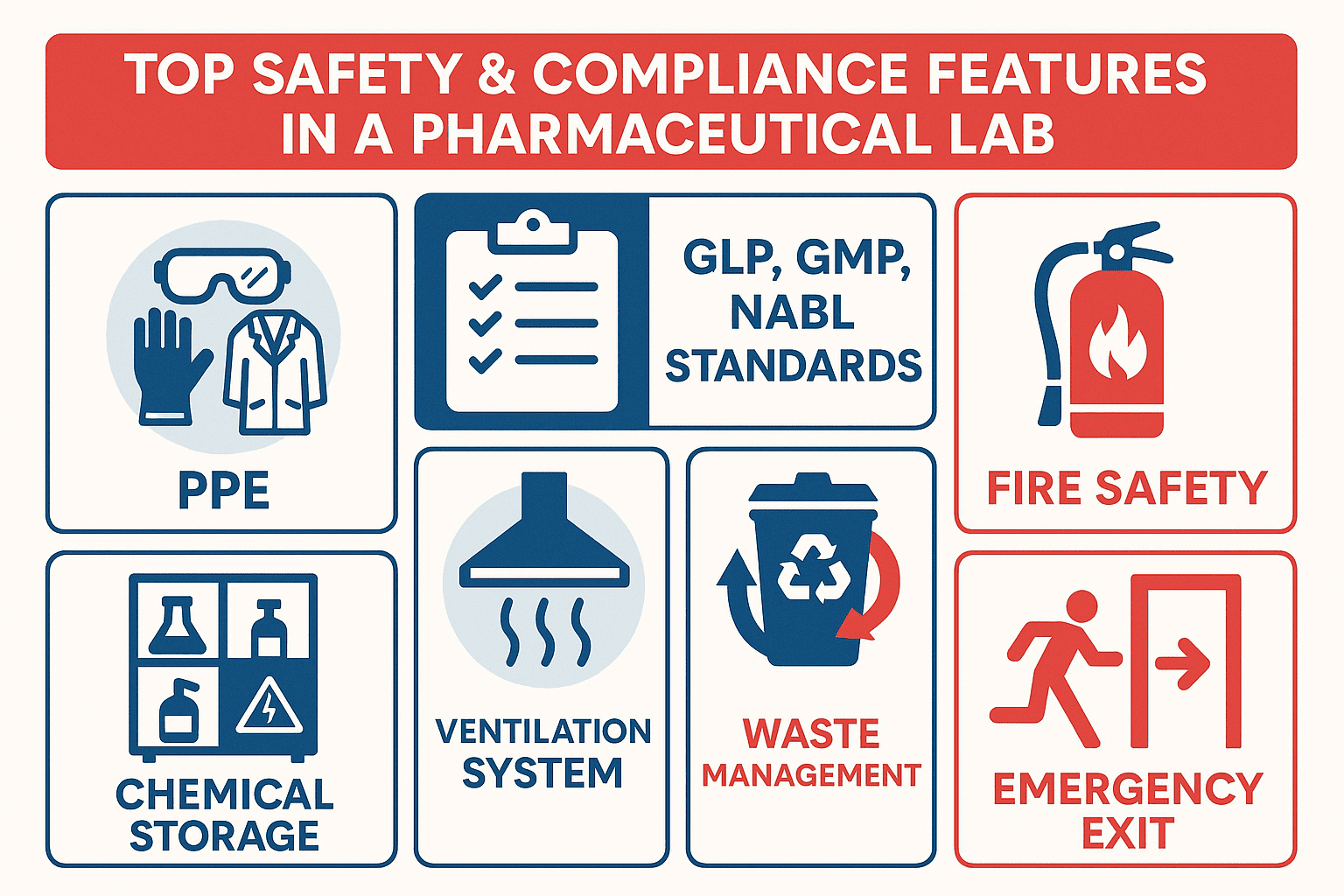

4- Safety and Compliance Standards

Safety is the cornerstone of pharmaceutical lab operations. Every lab must follow strict safety protocols to protect personnel and ensure regulatory approval. The key areas include:

- Fire Safety: Install fire extinguishers, alarms, and flameproof electrical fittings.

- Chemical Safety: Label all chemicals properly and store them in ventilated cabinets.

- Personal Protective Equipment (PPE): Ensure all staff use lab coats, gloves, goggles, and masks.

- Emergency Protocols: Develop clear evacuation and spill management procedures.

- Waste Disposal: Implement a system for segregating and disposing of biological and chemical waste.

All pharmaceutical labs in India must comply with national regulations such as the Drugs and Cosmetics Act, BIS standards, and guidelines issued by the Central Drugs Standard Control Organization (CDSCO).

5- Utility Systems and Environmental Control

Utility systems are the hidden support structure of a pharmaceutical lab. They ensure that every experiment or test is conducted under controlled and reliable conditions. These include:

- Water Systems: Purified water and distilled water systems are essential for analytical and microbiological tests.

- Compressed Air and Gas Supply: For operating instruments and maintaining sterile conditions.

- Electrical Systems: Uninterrupted Power Supply (UPS) for sensitive instruments.

- Temperature and Humidity Control: Critical for maintaining sample stability and data reliability.

- Clean Rooms: In sterile testing environments, cleanroom standards (ISO Class 7 or 8) may be required.

A well-maintained utility system minimizes downtime and ensures consistent laboratory performance.

6- Documentation and Digital Integration

In today’s digital era, laboratories are moving towards automation and paperless operations. Laboratory Information Management Systems (LIMS) help in managing samples, maintaining audit trails, and ensuring data integrity. Documentation is also vital for audits, inspections, and traceability.

Ensure that:

- Standard Operating Procedures (SOPs) are documented and accessible.

- Calibration, maintenance, and validation records are regularly updated.

- Electronic Data Management complies with ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, Accurate, and more).

Proper documentation is not just a regulatory requirement but also an operational advantage.

7- Manpower and Training

A pharmaceutical lab is only as good as the people who run it. Skilled staff with experience in analytical chemistry, microbiology, or pharmacology are vital for accurate results. Every employee should receive continuous training on:

- SOPs and regulatory updates

- Equipment handling and calibration

- Safety practices and emergency management

Periodic competency assessments ensure quality and reduce human errors.

8- Cost Planning and Budgeting

Cost planning plays a major role in setting up a new lab. The total investment depends on the scale, purpose, and sophistication of the setup. Here’s a general breakdown:

- Infrastructure & Furniture: 30–40% of total cost

- Instruments & Equipment: 40–50%

- Safety and Utilities: 10–15%

- Miscellaneous & Documentation: 5–10%

Budgeting should include future expansion plans, maintenance costs, and calibration expenses.

9- Regulatory Approvals and Certifications

Before starting operations, pharmaceutical labs in India must obtain necessary licenses and certifications. These include:

- GLP Certification (Good Laboratory Practice)

- NABL Accreditation for testing and calibration labs

- Drug Testing License from the CDSCO or State FDA

- Environmental Clearance for waste management and emissions

Compliance with these ensures global credibility and opens the door for international collaborations.

10- Special Considerations for Hospital Labs

When setting up labs within hospitals, additional Lab Setup Requirements in hospital must be considered. These include patient safety, biohazard management, and integration with clinical departments. Hospital labs must focus on rapid testing, accuracy, and sterile sample handling. Collaboration between hospital administration and lab specialists ensures smooth operation and compliance with healthcare regulations.

Conclusion

Establishing a pharmaceutical laboratory in India requires a balanced approach that integrates technical precision, safety, and compliance. Meeting all Lab Setup Requirements ensures that your facility not only functions efficiently but also passes audits from regulatory authorities with ease.

By focusing on Lab setup requirements in India—from infrastructure to certification—you can build a facility that drives innovation and quality in the pharmaceutical sector. And when extending these principles to healthcare environments, understanding Lab setup requirements in hospital becomes equally important for delivering safe, accurate, and reliable testing results.

A well-designed lab is not just a space—it’s a foundation for trust, innovation, and excellence in the pharmaceutical industry.