Setting up a modern laboratory in India is never just about equipment and furniture. It’s about creating a space where science, safety, and efficiency meet. Recently, our team completed a full Turnkey Laboratory project for a client in India, and the journey came with its share of challenges, problem-solving, and valuable lessons.

This article walks you through how we handled the process—from design to installation—while highlighting the key obstacles we faced and how we overcame them.

Step 1: Understanding the Client’s Vision

The client approached us with a simple but ambitious goal: a laboratory that meets international standards, supports multiple testing applications, and remains flexible for future expansion.

Before we moved into designs or layouts, we held multiple workshops with their internal team. These discussions helped us map out:

- The type of experiments they planned to conduct.

- Compliance requirements (both national and international).

- Space limitations in the existing building.

- Their preferred timelines and budget.

This early phase made it clear that off-the-shelf furniture and fragmented installations wouldn’t work. A single integrated approach—what we call Turnkey Laboratory solutions—was the only way forward.

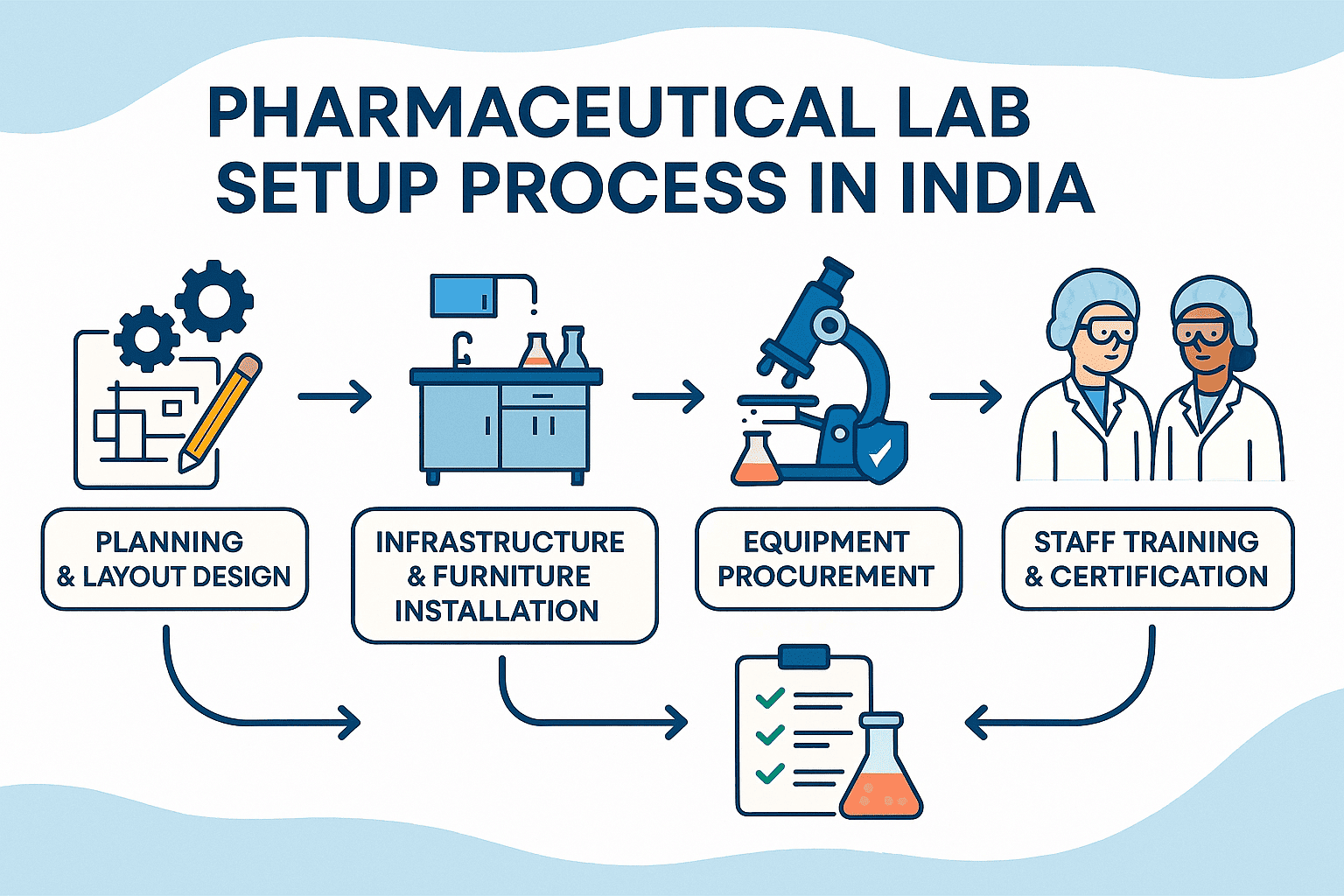

Step 2: Design & Compliance

The design stage was not only about maximising space but also about ensuring safety and compliance. Laboratories in India must follow specific guidelines related to ventilation, chemical handling, fire safety, and electrical layouts.

Our design process included:

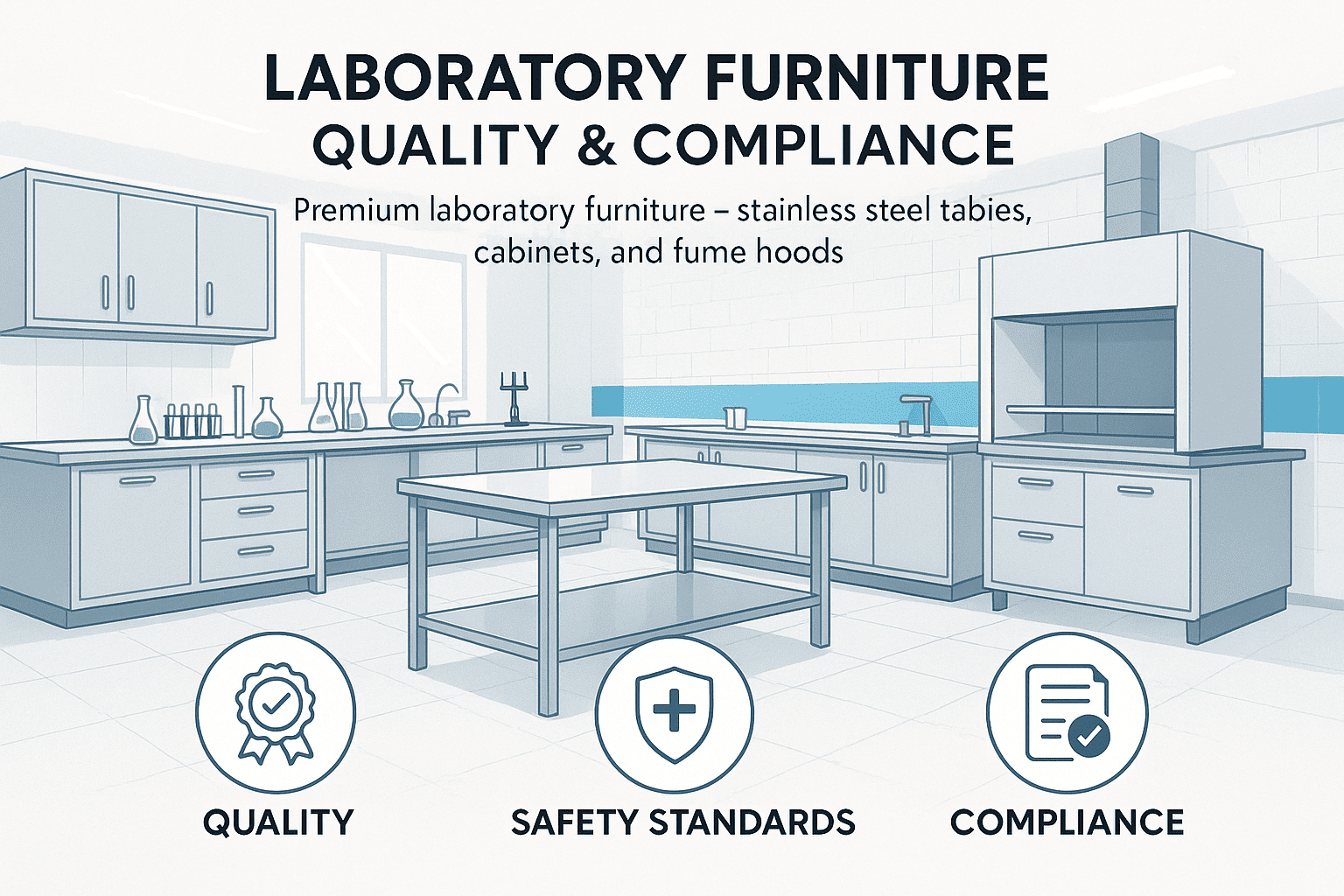

- Detailed CAD drawings to visualise every workbench, storage unit, and fume hood.

- Zoning of “clean areas” and “chemical areas” to avoid contamination.

- HVAC planning for air circulation and temperature control.

- Plumbing and electrical provisions to support sensitive lab instruments.

One of the biggest challenges was striking a balance between aesthetics and compliance. The client wanted a modern look with glass partitions and open spaces, but we had to ensure that safety barriers and airflow systems were not compromised.

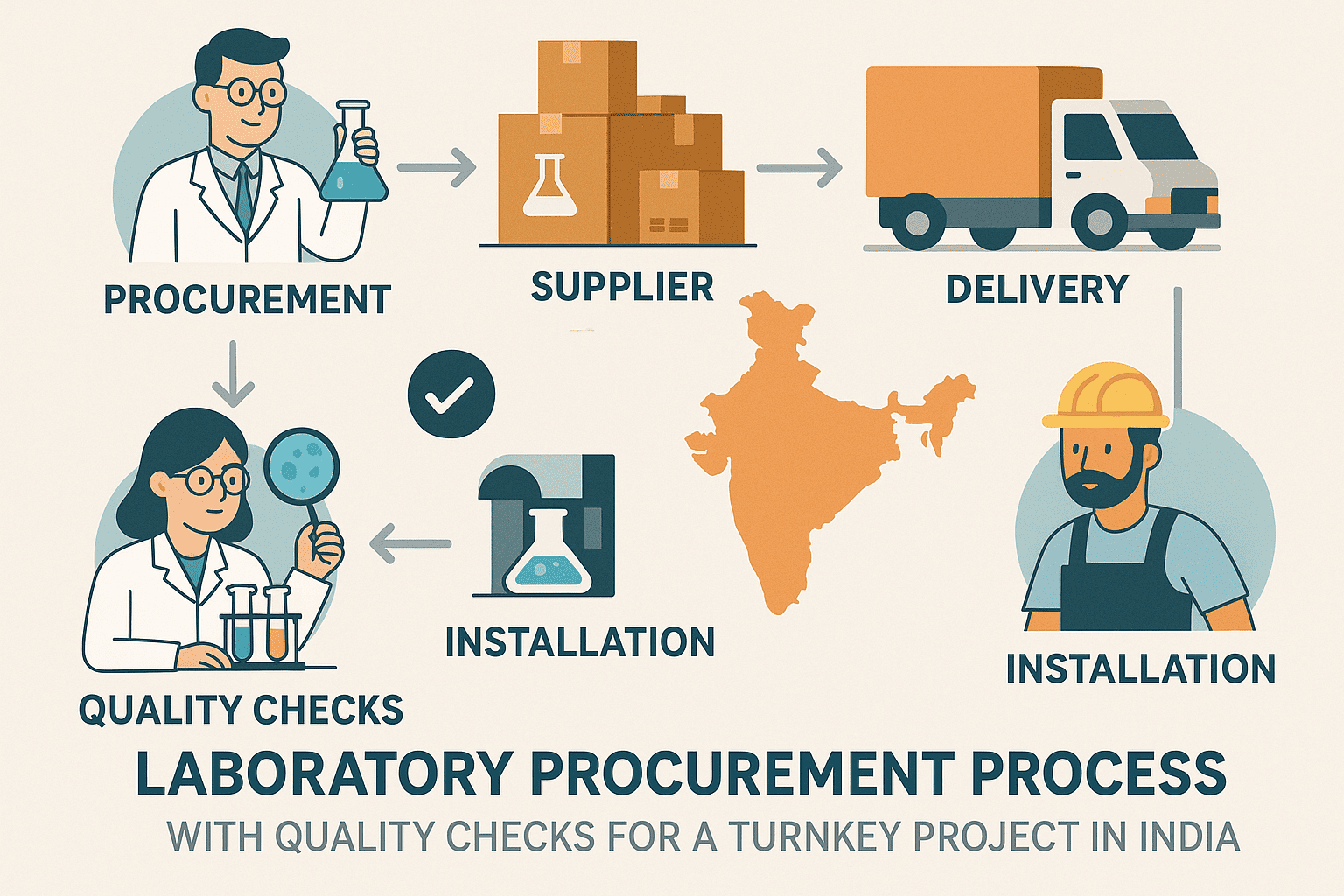

Step 3: Procurement & Quality Checks

When it comes to laboratory setups, procurement is where delays often happen. Vendors sometimes promise fast delivery but fail to meet technical requirements.

To avoid this, we created a strict quality checklist for every item—whether it was epoxy worktops, fume hoods, or lab stools. Each product went through inspection for chemical resistance, durability, and safety certifications.

We also partnered with reliable local and international suppliers, which helped us cut down delivery timelines. This is one of the strengths of Lab Turnkey Solutions—everything is coordinated under a single umbrella, reducing the friction of managing multiple vendors.

Step 4: Installation & Execution

Execution is where theory meets reality. Even the best designs face real-world obstacles during installation. In this project, our main challenges included:

1- Site Restrictions – The facility was inside an existing industrial building, which meant limited access for moving in heavy lab furniture and fume hoods.

Solution: We scheduled phased deliveries and used modular installations to fit equipment through restricted entryways.

2- Timeline Pressure – The client had regulatory inspections scheduled within a strict timeframe.

Solution: We adopted parallel workflows—while one team handled civil work, another team managed electrical and HVAC installations.

3- Utility Coordination – Integrating gas lines, plumbing, and electrical systems required precise planning to avoid clashes.

Solution: We used BIM (Building Information Modeling) software to identify overlaps before actual execution.

Step 5: Safety & Testing

Once the installation was completed, we conducted multiple rounds of testing. This included:

- Fume hood performance checks.

- Fire safety drills.

- Airflow and pressure balancing in controlled areas.

- Water leakage and load-bearing tests for worktops.

Testing not only ensured compliance but also gave the client confidence that their laboratory was fully operational and inspection-ready.

Key Challenges We Faced

Delivering this project wasn’t without roadblocks. Here are the biggest hurdles we encountered and how we dealt with them:

1- Regulatory Hurdles – Local approvals often take longer than expected. We prepared documentation in advance and coordinated with regulatory bodies early on.

2- Vendor Delays – Some imported equipment was delayed at customs. We mitigated this by keeping buffer stock of essential lab furniture.

3- Budget vs. Quality – The client wanted premium quality but within a controlled budget. We offered a hybrid approach: imported equipment where necessary, but locally sourced solutions where possible.

Learnings From the Project

Every project teaches something new. Here are our biggest takeaways:

1- Early Planning Saves Time – Involving compliance officers and engineers from day one prevents redesigns later.

2- Integration Is Key – A laboratory is not just furniture and equipment—it’s an ecosystem where every utility must work together.

3- Flexibility Matters – Modern labs need modular setups that can adapt to future changes.

4- Communication Builds Trust – Constant updates to the client reduced stress and built confidence.

Why Turnkey Works Best

Looking back, this project reinforced our belief in the value of Turnkey Laboratory solutions. Instead of the client managing multiple contractors, suppliers, and consultants, everything was handled by a single team.

This approach not only saved time but also reduced costs in the long run. More importantly, it gave the client a laboratory that was functional, safe, and ready for operations without unnecessary delays.

Final Thoughts

Delivering a complete laboratory setup in India comes with challenges—regulatory hurdles, vendor coordination, space limitations—but with the right planning and execution, it’s absolutely achievable.

This project reminded us that science deserves an environment that supports innovation without compromise. And that’s exactly what a well-executed Turnkey Laboratory project can deliver.