A laboratory setup is one of the most critical investments for any scientific, industrial, educational, or research-based organisation. A well-designed lab supports accuracy, safety, productivity, and long-term performance. However, many projects fail or face costly delays because of poor planning, overlooked design elements, and mismanagement at different stages. To ensure smooth execution, it is important to recognise the Mistakes to Avoid When Planning a Lab Infrastructure Project and implement the right strategies from the very beginning.

Whether you are upgrading an existing facility or creating a new one from the ground up, avoiding these mistakes can save time, reduce costs, and ensure you build a highly functional and efficient laboratory. Below are the 10 most common mistakes you must avoid.

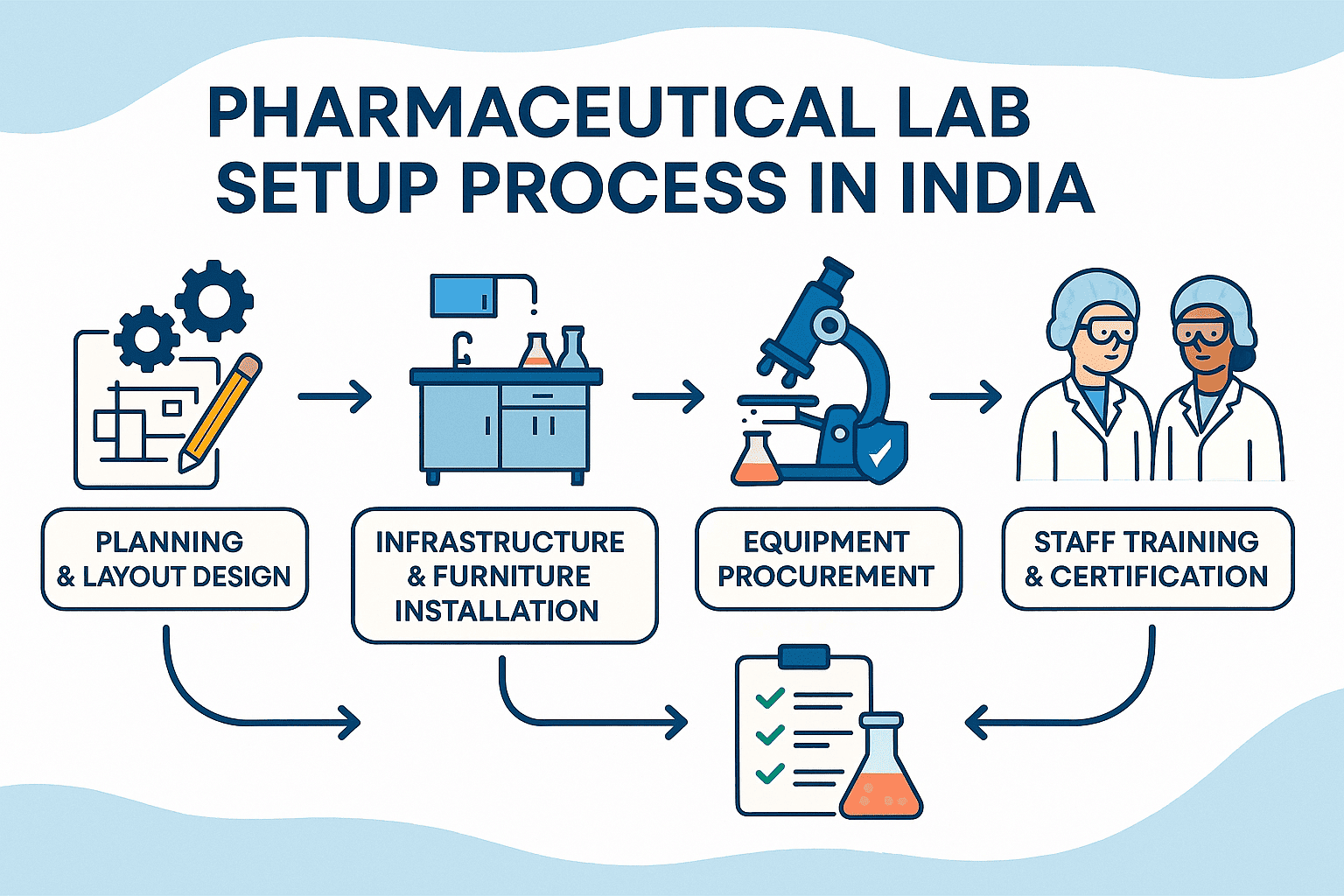

1- Not Understanding Functional Requirements Early

One of the biggest errors during a lab setup is starting the design without understanding the operational needs. Every laboratory has specific workflows, equipment requirements, and safety standards. Failing to map these early can result in poor layout, space shortages, and inefficient movement inside the facility.

Before finalising the layout, it’s important to define:

- What type of experiments or processes will be conducted

- What instruments will be used

- Future expansion possibilities

- Storage and equipment zoning

A clear understanding ensures the lab design supports the actual working environment.

2- Ignoring Regulatory and Safety Standards

Compliance is a crucial part of any laboratory environment. Many organisations overlook statutory guidelines related to ventilation, electrical safety, fire control, PPE access, and chemical handling. Non-compliance not only delays project approvals but also poses serious safety risks.

Each laboratory setup must follow:

- Local and national safety codes

- International standards (where applicable)

- Environmental regulations

- HVAC and biosafety guidelines

Ignoring any of these can lead to expensive redesigning later.

3- Poor Space Planning and Inefficient Layout

Space utilisation is one of the most challenging aspects of Planning a Lab Infrastructure Project. Poorly designed labs often suffer from overcrowding, insufficient movement space, and improper equipment placement. A good design ensures:

- Clear workflow patterns

- Adequate spacing between instruments

- Error-free sample movement

- Dedicated zones for wet and dry labs

A strategically planned layout improves team productivity and reduces chances of accidents or workflow interruptions.

4- Underestimating Electrical and Mechanical Requirements

A lab setup relies heavily on stable power supply, proper grounding, gas lines, exhaust systems, and uninterrupted mechanical support. Many planners overlook future load requirements, eventually leading to malfunctioning equipment or unexpected downtime.

To avoid technical failures, you must:

- Plan separate circuits for heavy equipment

- Install UPS or backup power

- Ensure proper gas line routing

- Maintain clear access for maintenance

A strong mechanical and electrical foundation ensures uninterrupted lab operations.

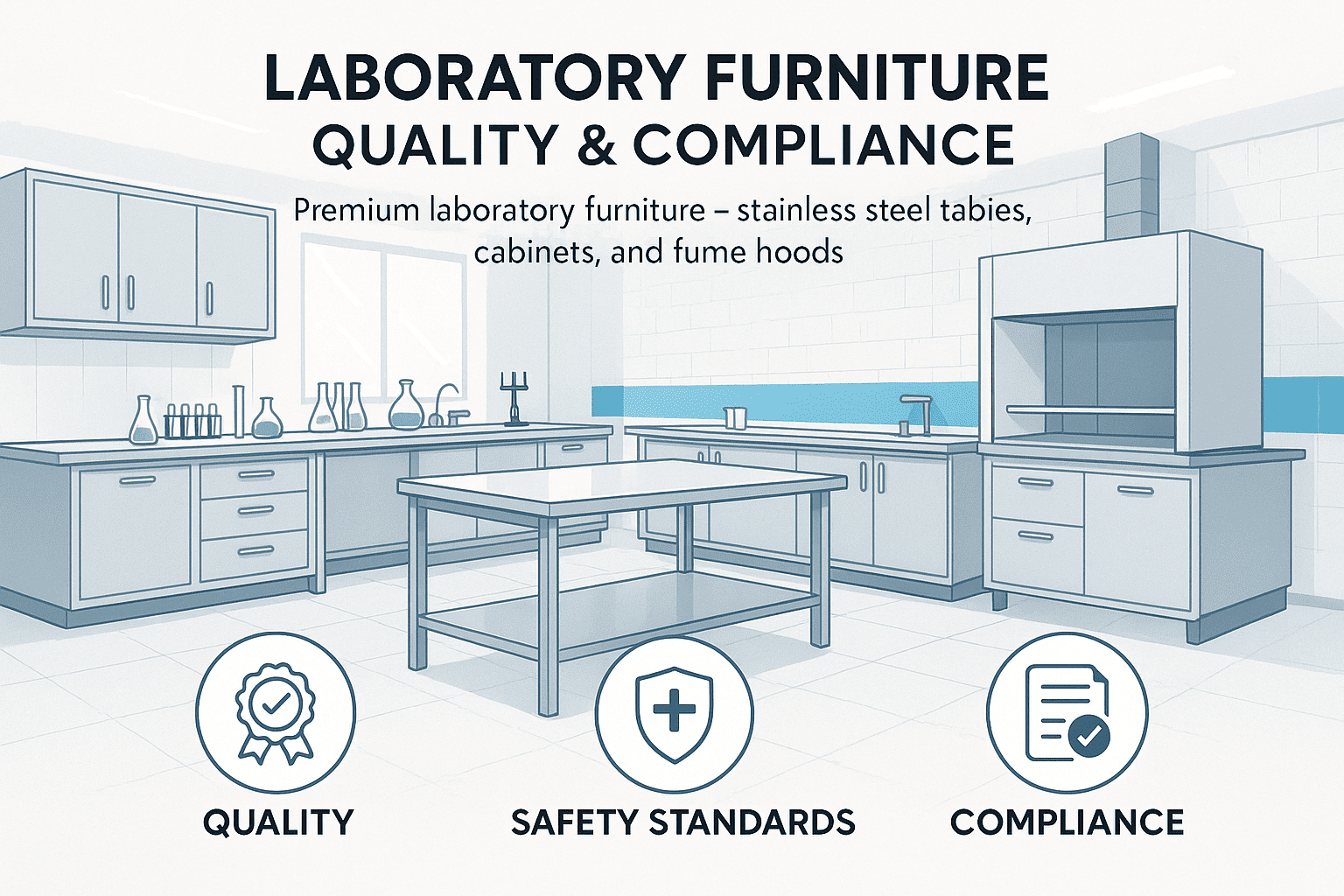

5- Selecting the Wrong Materials and Furniture

Lab furniture must withstand chemical exposure, heat, weight, and constant usage. Choosing substandard materials might reduce initial costs, but frequent repairs will make the overall spend much higher. Always choose:

- Chemical-resistant worktops

- Sturdy metal or modular furniture

- High-quality fume hoods and storage units

Proper furniture contributes significantly to safety and long-term reliability.

6- Neglecting Ventilation and Airflow Requirements

Ventilation is essential in labs that handle chemicals, biological samples, fumes, or airborne contaminants. Poor ventilation can expose staff to health hazards and compromise experiment accuracy.

You must ensure:

- Proper exhaust systems

- Correct fume hood placement

- Balanced airflow and pressure settings

- Controlled temperature and humidity

A well-maintained HVAC system also extends equipment life and ensures a safe working environment.

7- Not Planning for Storage and Waste Management

A common mistake is underestimating storage needs for reagents, chemicals, and consumables. Similarly, an efficient waste management system is often ignored during planning.

A good lab must include:

- Fireproof chemical cabinets

- Refrigerated storage (if needed)

- Biohazard, chemical, and general waste bins

- Clearly marked disposal zones

Well-planned storage reduces clutter and prevents contamination.

8- Overlooking Digital Infrastructure and Connectivity

Modern laboratories rely heavily on digital tools, smart equipment, automation systems, and cloud-based monitoring. Not planning for this during the initial design phase can lead to messy cable management and poor connectivity.

Your lab should support:

- High-speed internet

- Network-ready instruments

- Data backup systems

- Sensor-based monitoring

Digital readiness improves accuracy, security, and operational efficiency.

9- Not Accounting for Future Expansion

Many labs are designed only for current needs, leaving no room for growth. As research expands, new instruments, personnel, and functions require additional space.

Forward-thinking planners always:

- Keep spare electrical and mechanical capacity

- Allocate flexible modular spaces

- Plan scalable equipment zones

Future-proofing ensures your lab remains relevant, adaptable, and cost-efficient for years.

10- Poor Coordination Between Teams

A lab infrastructure project involves architects, engineers, contractors, lab planners, and end-users. Miscommunication among these teams can lead to design errors, installation delays, or technical mismatches.

To avoid this, ensure:

- Clear communication channels

- Regular progress reviews

- Collaborative design approvals

- Early involvement of lab users

Coordination is the backbone of successful Laboratory infrastructure development.

Conclusion

A well-planned laboratory setup boosts efficiency, accuracy, and long-term operational success. By avoiding these 10 common mistakes, organisations can eliminate unnecessary expenses, ensure compliance, and create a safe working environment.

Successful lab planning is not just about building a facility—it is about understanding the science, workflow, and future needs of your organisation. With the right approach, your laboratory infrastructure becomes a reliable asset that supports research and innovation for years to come.